CONSTEEL

CONSTEEL CONSTEEL

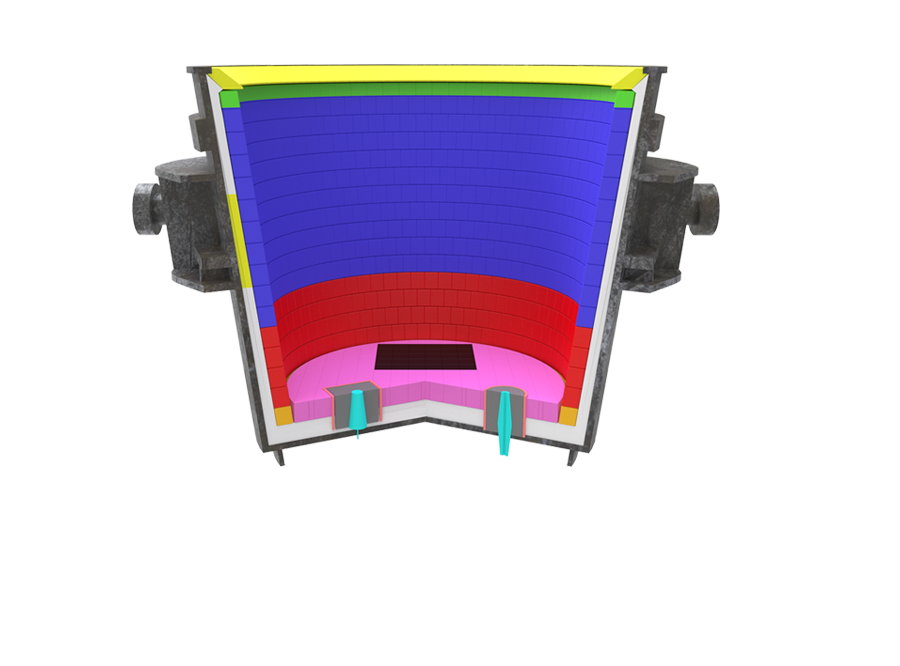

CONSTEELThere are many kinds of refractory materials for CONSTEEL ladles lining, and the refractory materials used for different ladle functions are different. CONSTEEL will design the most suitable refractory materials for customers according to the following four points:

Refining process The influence of the choice of ladle lining;

The influence of die casting and continuous casting process on the choice of ladle lining;

The influence of smelting steel on the lining of ladle;

The use of the lining of the ladle Impact.

COPYRIGHT © 2019 CONSTEEL. ALL RIGHTS RESERVED

Magnesia carbon brick EAF refractory manufacturer Ladle purging plug Consteel EAF monolithic Tapping well block Ladles metallurgical addictive