CONSTEEL

CONSTEEL CONSTEEL

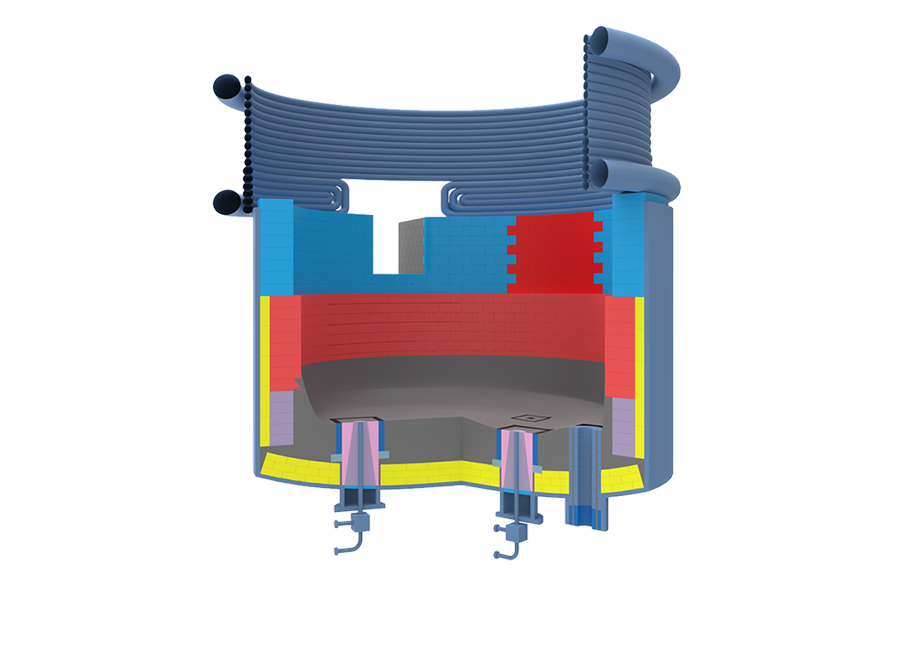

CONSTEELElectric furnace is a relatively environmentally friendly steel smelting equipment. In order to minimize the frequency of shutdown maintenance, increase the output of steel mills and furthemore improve customer benefits, relies on.

CONSTEEL Metallurgy is pround to provide a reliable range of shaped and amorphous refractory products based on decades of industry experience and knowledge accumulation for the lining project of electric furnace refractory solutions.

COPYRIGHT © 2019 CONSTEEL. ALL RIGHTS RESERVED

Magnesia carbon brick EAF refractory manufacturer Ladle purging plug Consteel EAF monolithic Tapping well block Ladles metallurgical addictive